Acid Core Solder Uses

The acid core is a type of.

Acid core solder uses. Acid core solder is used to attach pieces of sheet metal or plumbing together. Examples of this include joining together parts of engines in cars or other machinery and in plumbing to strip the layer of oxidation off the surface of pipes as the solder melts allowing it to form a waterproof joint. Hj az acid core is never used for electical connections. Includes flux core with highly active cleaner.

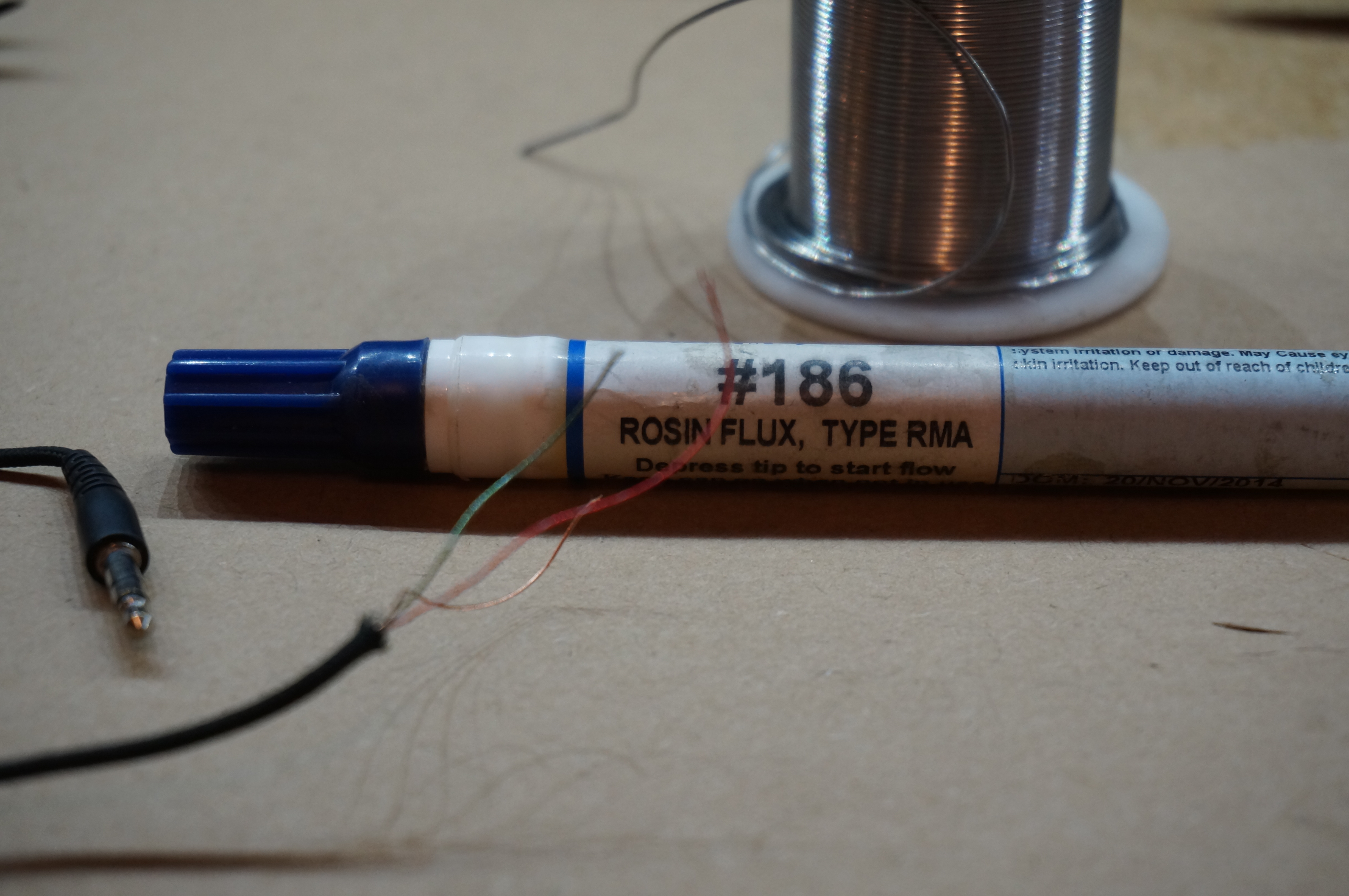

Acid core is used for plumbing and rosin core is used for electronics. Acid core should never be used if you are sweating your pipes rather than making a simple repair. The acid core in the solder can be said to clean the oxidation off the metal making for a satisfactory joint. Flux is designed to improve electrical contact and mechanical strength in solder joints.

What is acid core solder used for. The uses for acid core solder include the joining of oxidized metals. There are mainly two types of flux cores. The name acid core tells us the flux is an aggressive type designed to solder steel as well as other metals.

Heat sources for cored solders can be air fuel torches or soldering irons and guns. They require rosin core otherwise they will corrode and lose conductivity. Flux residue from acid core solder must be removed after soldering to avoid potential part corrosion. Container size 1 lb.

The acid somewhat cools the area you re soldering so you need to apply. It also helps the solder spread out reduces surface tension transfer heat and acts as a protective blanket to keep oxygen away from the metal until solder displaces it. You cannot use any core solder to make copper pipe connections. Contents 60 lead 40 tin.

If it is just a small can of flux toss it and buy a new one when you need to make some. Acid core and rosin core. The acid core in the solder cleans the oxidation off the metal making for a satisfactory joint. While it may be suitable for mending holes in aged pipes it should be cleaned off totally once the seal is made.

The uses for acid core solder are effective for galvanized metal in most cases and other similar metals that would be difficult to join using normal solder. Application for non electrical uses such as repairing tools radiators automotive parts and sheet metal. I have a roll of acid core solder any good. The solder you use for plumbing jobs typically has a solid core and to make it adhere you have to apply acid based flux.

Item acid core solder.